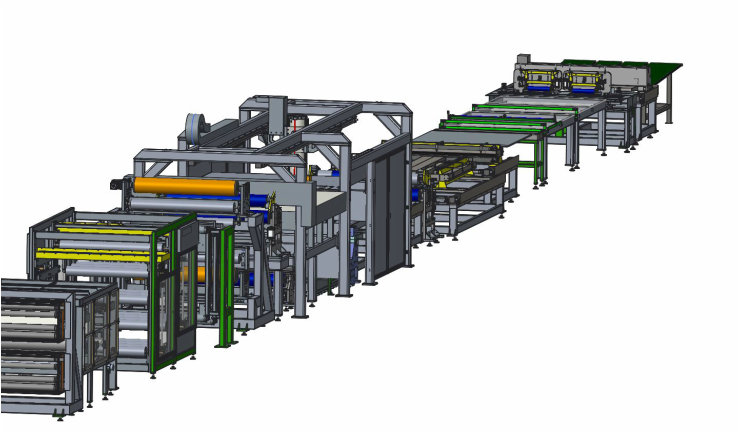

Project Profile:

•Denver based startup firm that developed smart window technology in an R&D environment (thin film laminate)

•At the time of engagement, product was produced manually, at the rate 4 man-hours per 1ft2

•Maximum production size was 16x24”

Objectives:

•Develop an approach to automate the production process

•Continuous operation with max production rate of 70ft2/min

•Maximum panel size of 78x78”

•Integration of QC station

•Minimal operator involvement

•Process development and validation through small-scale test rig

•Machine specification development

•Specification of vendor supplied products

•Design, optimization of ~30 process cells

•Generation of complete engineering package (3D, 2D files, BOM’s, PL, assembly & calibration documents, detailed machine spec)

•Denver based startup firm that developed smart window technology in an R&D environment (thin film laminate)

•At the time of engagement, product was produced manually, at the rate 4 man-hours per 1ft2

•Maximum production size was 16x24”

Objectives:

•Develop an approach to automate the production process

•Continuous operation with max production rate of 70ft2/min

•Maximum panel size of 78x78”

•Integration of QC station

•Minimal operator involvement

•Process development and validation through small-scale test rig

•Machine specification development

•Specification of vendor supplied products

•Design, optimization of ~30 process cells

•Generation of complete engineering package (3D, 2D files, BOM’s, PL, assembly & calibration documents, detailed machine spec)

RSS Feed

RSS Feed